Weiboldshausener Str. 1

91792 Ellingen

Germany

Tel.: +49 9141/86004-10

Fax: +49 9141/86004-19

info@asw-karg.de

www.karg-gmbh.de

Knit wire meshes

The knit wire mesh – technical multitalent – cheap to make.

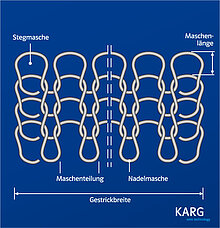

ASW-KARG knit wire meshes are made from continuous wire in the form of intermeshing stitches. The extremely small contact surfaces at the contact points resulting from the profile produce a meshwork which is three-dimensionally flexible and boasts ideal elasticity and stretching characteristics. Precisely attuned, it allows the desired technical function to be produced in the products in which it is used. You can see the schematic view and the defining specialist terms in the adjacent diagram.

How a knit wire mesh is made

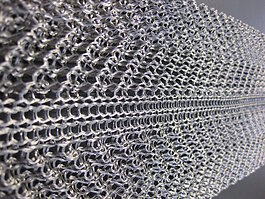

A sleeve which is produced using the circular knitting method is generally processed further as a web which is laid flat. These webs can be processed further by being folded and placed in position to form packages and by subsequent compaction to produce knit wire mesh elements. They are supplied in the form of reels, as a blank cut to size, ready-made into packages or elements. The ASW-KARG technology makes it possible to conform to the tighest tolerances and make products cost-effectively at the same time.

The knit wire mesh in use