Weiboldshausener Str. 1

91792 Ellingen

Germany

Tel.: +49 9141/86004-10

Fax: +49 9141/86004-19

info@asw-karg.de

www.karg-gmbh.de

Droplet separators

ASW-KARG separators separate, thanks to a special structure of different knit mesh layers, liquid mist fractions and dusts effectively and above all economically from air or process gases.

Applications are:

Chemical and petrochemical industry, distillation, rectification columns, refrigeration and vacuum technology, vehicle technology, mechanical engineering, air conditioning, kitchen and domestic engineering.

• Absorption and distillation columns • evaporator and detensioning systems • rectification systems • vacuum and compressed air systems • sulphuric acid production • oil separators.

In the separation process, aerosols flow through the knit wire mesh packing, impact against the wire surface on account of their moment of inertia, come together at the mesh junction points and drop down as relatively large droplets. The separating performance is dictated predominantly by the void volume and the specific wire surface of the knit mesh, and also its inflow velocity. Using different materials and combinations thereof, we produce highly efficient separators for a wide range of different objectives. With low pressure losses, separation levels of up to 99.9% are achieved. Our droplet separators are based on 3 separating mechanisms. Inertia separation, separation through the barrier effect and diffusion separation. With our extensive selection of materials, we can also supply tailor-made knit wire mesh packs for special applications featuring highly corrosive media, for example.

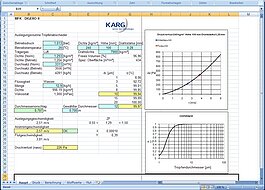

With our calculation program "DIGERO", which we have developed ourselves, we are able to calculate fractional separation outputs and pressure losses for each application individually.